PRODUCTIVE, PRECISE AND WELL CONSTRUCTED

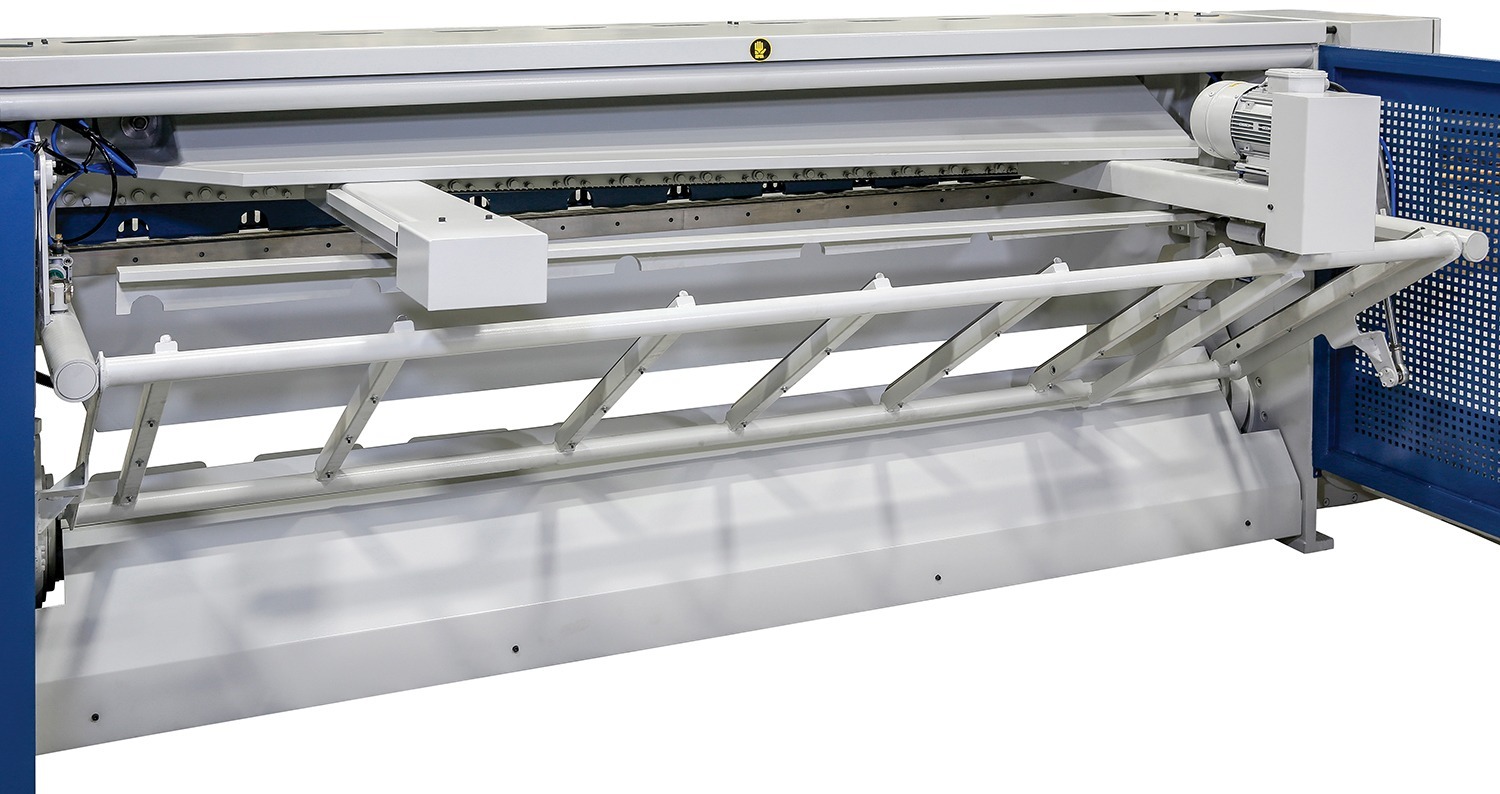

These Burnet mechanical shears are machines designed with the greatest care to offer an optimal experience to the operator. They are fast, precise and easy to adjust, which improves the efficiency of your work. Additionally, their unique design simplifies machine maintenance, helping to reduce total equipment cost.

Burnet shears are versatile and offer a multitude of interesting options. For example, you have the option of controlling your shears using a digital control for more precise and automated use. In addition, they can be equipped with a rear pneumatic support, allowing the cut material to be directed backwards or forwards, on the operator side, using a simple lever. This adds even more flexibility and convenience to your cutting process.