Main features

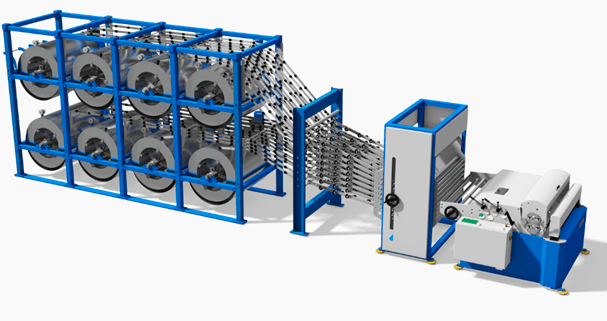

Automatic cut to length

- Slitting, cutting and straightening.

- Digital display for positioning the rip blade.

- Straightening unit with 4 straightening rollers.

- Adjustable speed up to 30 m/min.

- Maximum sheet width 1250 mm.

- Maximum sheet thickness 1.25 mm.

- Three slitting blades as standard.

Multi-reel automatic unwinding system

- Two-story structure with 8 unwinders

- Maximum load of 5 t/unwinder

- Maximum coil width 1250 mm.

- Maximum coil diameter 1100 mm.

- Height of the structure 3400 mm.

- Structure width 2300 mm.

- Coils can be loaded using an overhead crane or forklift.

- Unwinding speed 0 - 30 m/min.

- With automatic loop control and sensors.

- Each unwinder has its own motor for unwinding.

- Pneumatic plugs for waiting reels.

- Continuous sheet guide tracks to the reel selector.