Main features

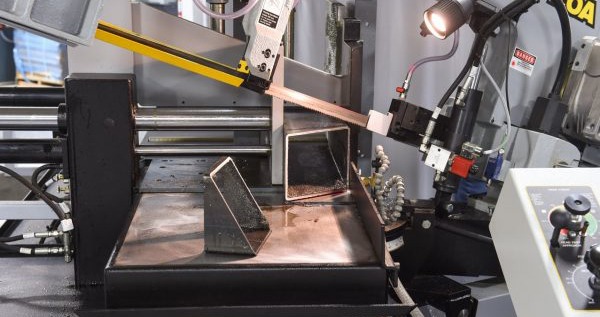

- Heavy duty cast iron saw head, easy to pivot, up to 60 degrees in one direction.

- The cast iron shuttle allows automatic indexing up to 27" in a single stroke. Driven by ball screw and stepper motor.

- 5 HP VFD. True direct blade drive - no belts/pulleys.

- The on-demand hydraulic system saves energy.

- The blade chamber separates the material from the cut piece, extending blade life.

- Cast iron band wheels

- PLC, touch screen control, programmable up to 100 jobs with 20 in queue

- Replaceable blade brush

- Sturdy steel base

- Easy-to-read angle scale with angle locking mechanism

- Cast iron guide arms mounted on linear rails are adjustable for proper spacing.

- Easy access electrical panel

- Full Capacity, Full Stroke Hydraulic Vices

Out of stock switch - Mechanical belt tension with digital display

- Positive hydraulic feed of the saw head

- Preset and replaceable carbide guide inserts

- Security door locks

- Watering liquid with flushing hose

- Laser light

- Work lamp

- Variable vise pressure