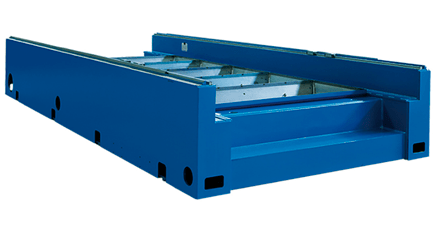

- A monolithic structure for greater precision and long-term stability

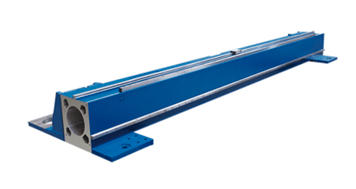

- Lightweight and very resistant gantry allowing higher speeds and accelerations

- Synchronized gantry driving on both sides for greater precision

- Guaranteed for 5 years on the frame (standard models)

- Very appreciable speeds and accelerations

- Very reasonable price of spare parts and good availability

- Siemens motors, drives and digital controller

- Alpha Wittenstein Pinions and Racks

- IPG resonator and Precitec cutting heads