Main features

- Software control and options:

- POS 2000 Professional graphic control

- Monitor on the front of the machine, integrated into the housing - rotatable

- Radius function

- PC version (external programming), 1. license

- Remote maintenance (connection via RJ45 network cable to be provided by the customer)

- Gauge :

- Motorized rear stop MAH 25R, working range 30 - 1600 mm, motorized adjustment by ball screw

sheet metal support table with balls

- Motorized rear stop MAH 25R, working range 30 - 1600 mm, motorized adjustment by ball screw

- Clamping beam:

- Stroke 500 mm

- 45° geometry.

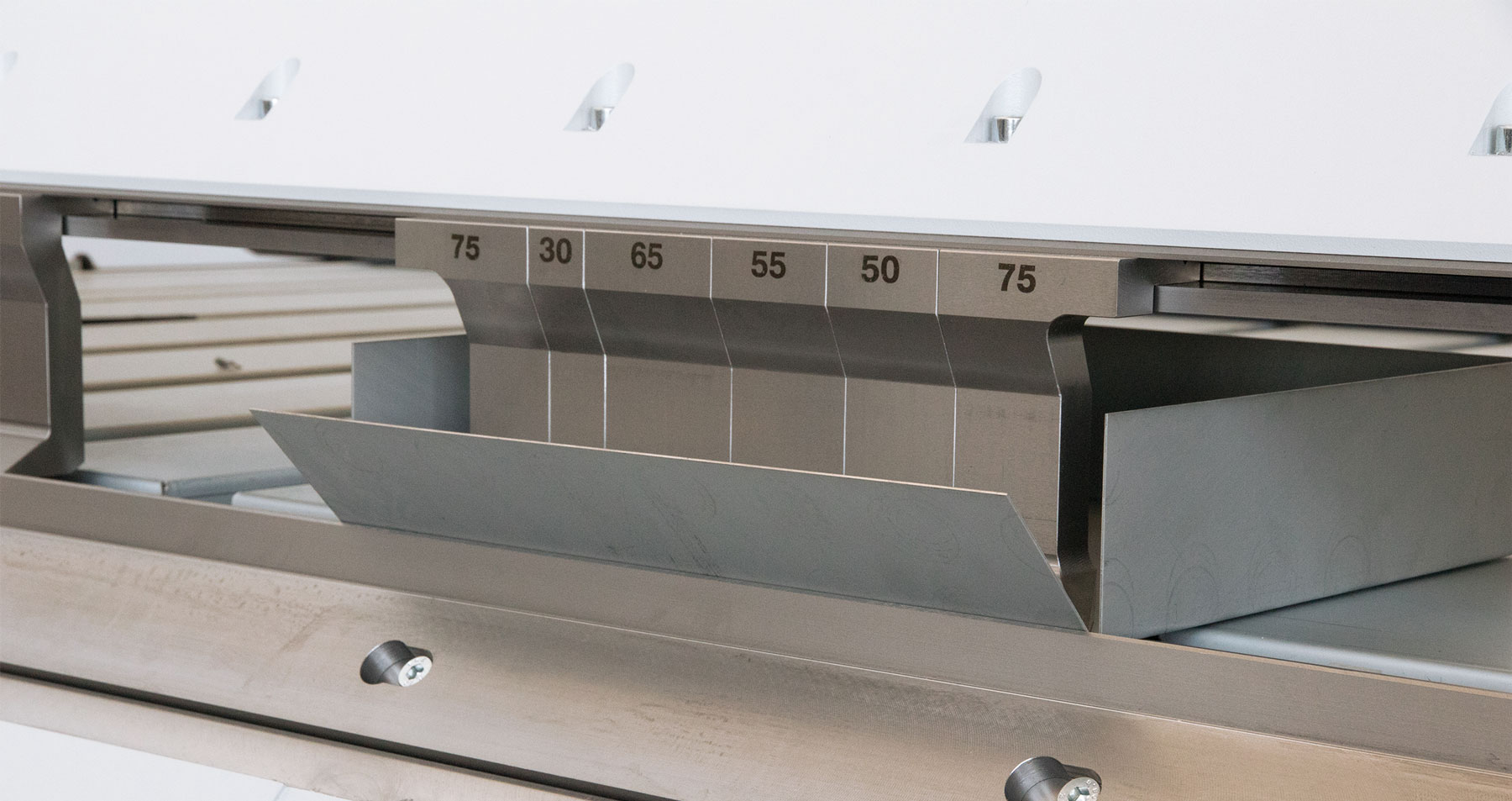

- WZS 2500 tool clamping with hydraulic clamping

- Folding beam:

- Max. folding angle : 180°.

- WZS 1000 tool clamping with mechanical clamping

- Motorized adjustment of the folding beam 60 mm

- Motorized crowning device

- Lower beam:

- Motorized adjustment of the lower beam 60 mm

- WZS 17000 tool clamping with mechanical clamping

- Work safety:

- Movable foot switch on the guide rail

- Safety enclosure on the left and right of the machine with two shelves each

- Work:

- Lower beam blade without finger grooves (minimum dimension 120 mm) or with finger grooves (minimum dimension 30 mm), hardened tools, nitrate.

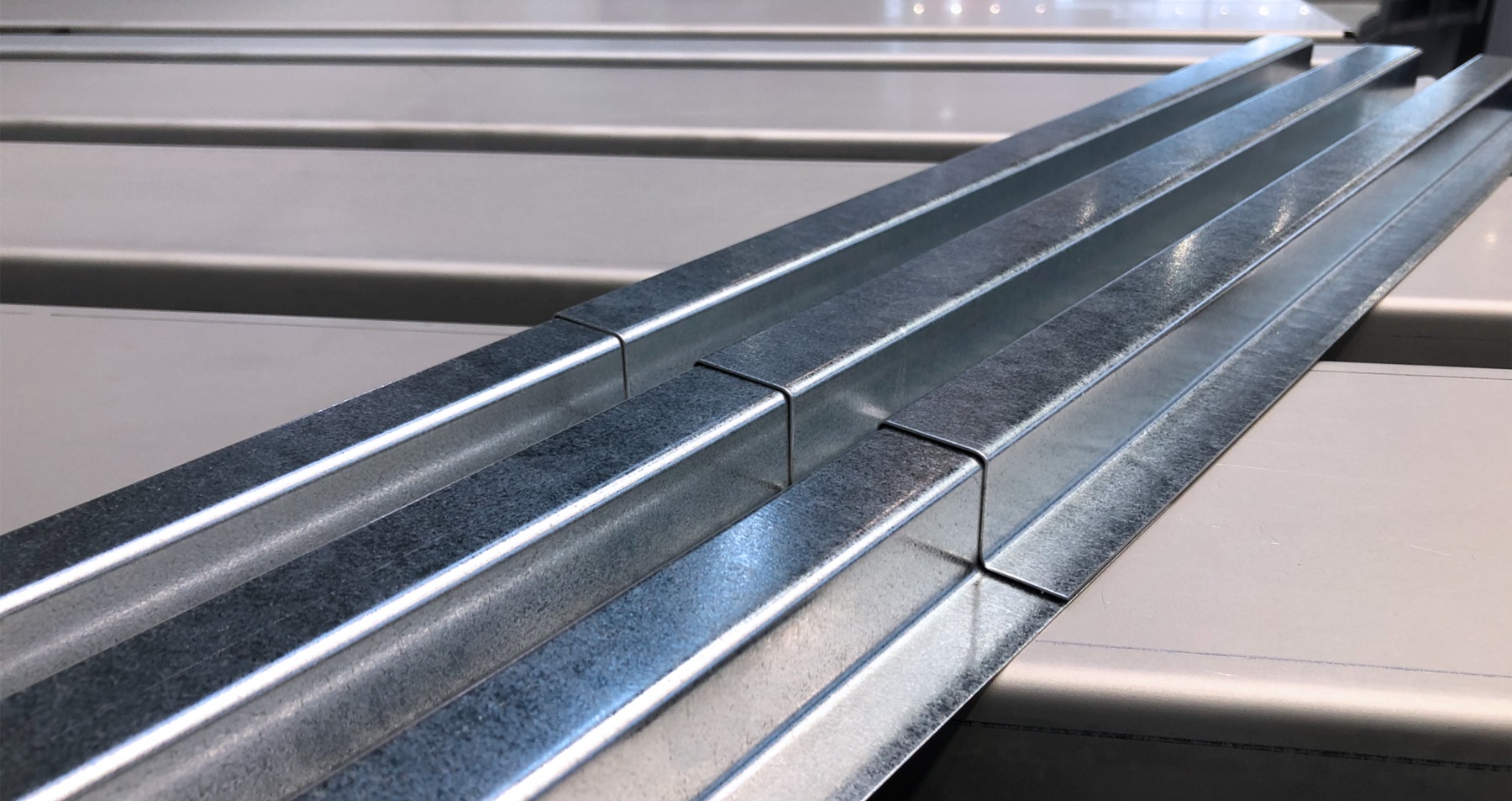

- Folding blade 2 pieces, h = 110 mm, width = 18 mm, and reinforced folding blade, 2 pieces h = 110 mm, width = 112 mm

- All tools approx. 1100 N/mm², induction hardened, phosphated

- Standard tool-less machine with clamping beam

- Others :

- 37 kW drive motor

- Anchor plates with dowels