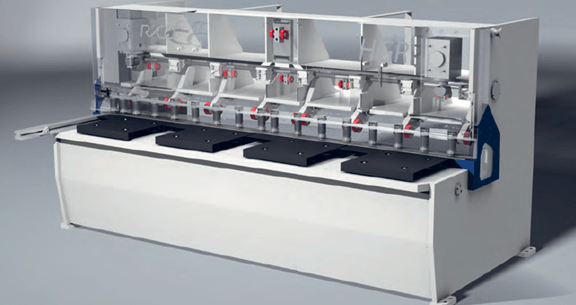

Main features

- Vertical section

- Variable cutting angle

- Elgo P40 CNC control panel

- Rear stop equipped with ball screws and linear guides

- Retractable rear stop

- Variable cutting length

- Variable cutting length 1000 mm squaring arm

- LED front lighting

- Progressive load retaining cylinders, fitted with a progressive tip, fitted with a Teflon tip

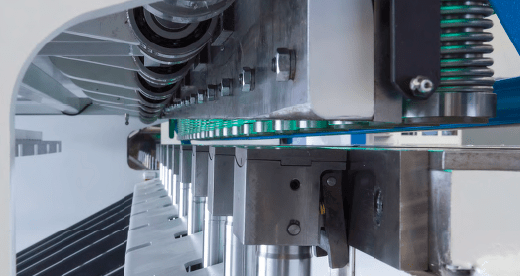

- Release mechanism between the blades allowing easy regulation

- RAE system: automatic retraction of the rear gauge from the back gauge during the cutting process

- Bright cutting line

- Continuous cutting or cycle by cycle

- Independent pickup (pre-selected)

- Front table with ball joints

- Hour counter

- Rear cover with photoelectric barriers (Category IV)

- Suspended pivoting control panel

- Easy hydraulic circuit bleeding system

- Standby function