Main features

- Support arms (2 or 3 depending on model)

- Estun E21 back gauge controller

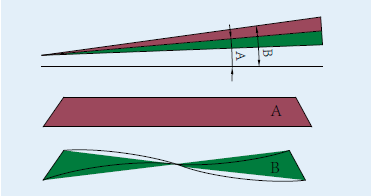

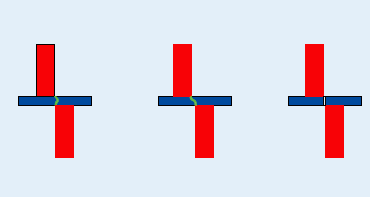

- 4-sided knives for top and bottom

- Notched table with transfer plates on balls

- Highly resistant polyurethane paint

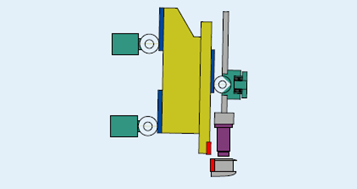

- Quick adjustment of blade clearance from the front

- Solid rear protection with photoelectric cells

- Front protective mesh with inserts for narrow cuts

- Removable operating console and two-point emergency stop

- Front squaring arm 39" graduated (in/mm, longer optional)

- Adjustment of the knife angle from the front (minimizes deformation)

- Motorized rear stop with digital reading (retractable at end of travel)

- Reliable electrical/hydraulic components & quickly available

(REXROTH, HYDAC, ABB, SIEMENS, SCHNEIDER, FUJI, etc.)