NEW LEVELS OF PRODUCTIVITY AND CAPACITY

The Schroeder MAK 4 Evolution Digital Folding Machine offers a robust yet elegant solution to maximize the efficiency of your production department. You can now bend a wide range of parts, whether large or small, with maximum efficiency, eliminating wasted time and labor.

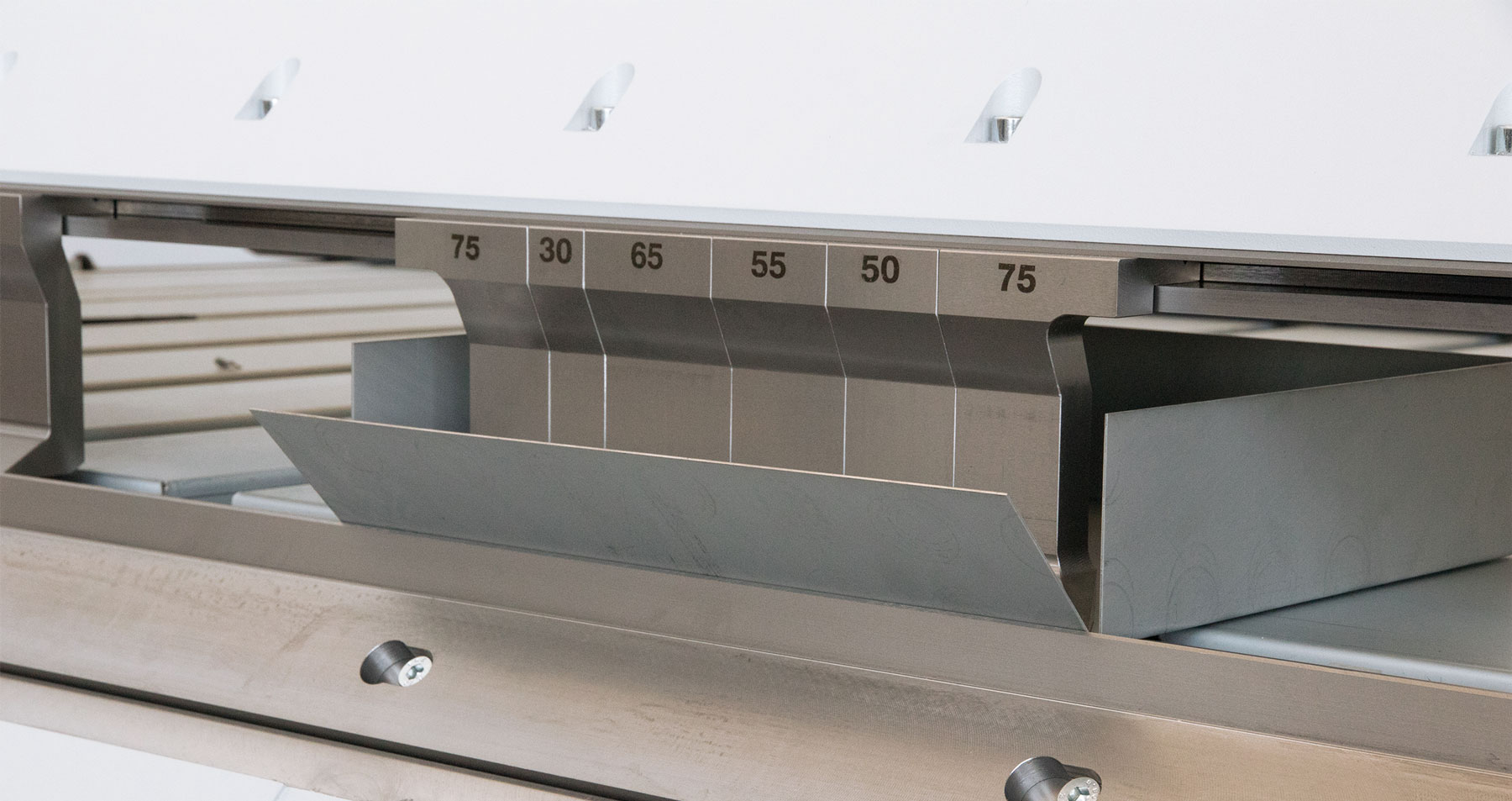

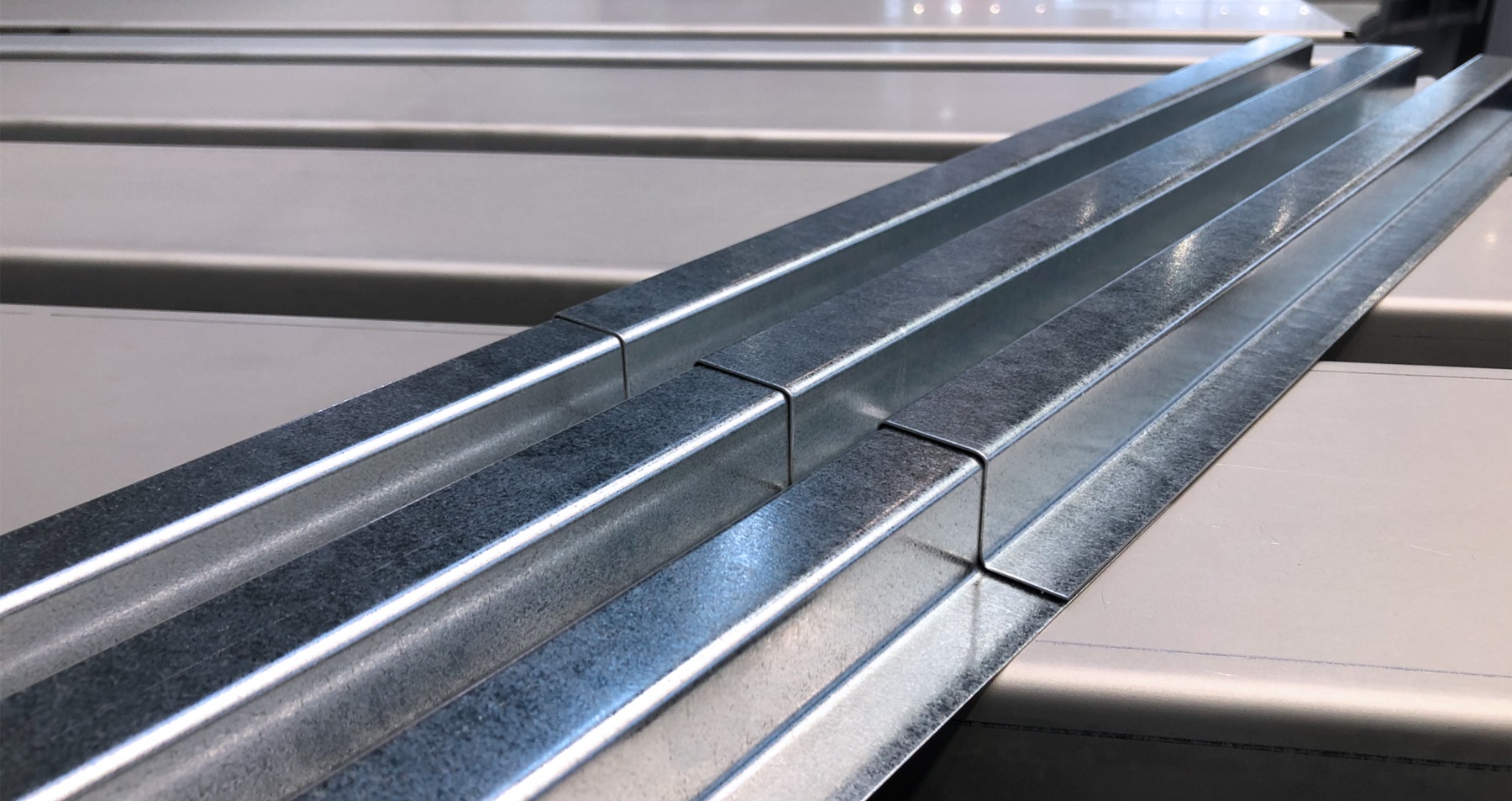

With the automatic tool change system, compatible with tools up to 25cm in height, you eliminate costly setup downtime. Bi-directional, up-and-down bending eliminates the need to turn parts, allowing you to do without a second operator. Plus, the dual-zone vacuum gauging system doubles your output by bending two parts simultaneously.

This technologically advanced design allows you to run processes in parallel, eliminating wasted time and unnecessary movements, while achieving new levels of productivity and capacity. The Schroeder MAK 4 Evolution Digital Folding Machine is the perfect choice to improve the efficiency of your production department. Don't waste any more time and contact us now to find out more.