Main features

- POS 2000 Professional graphic control on swivel arm

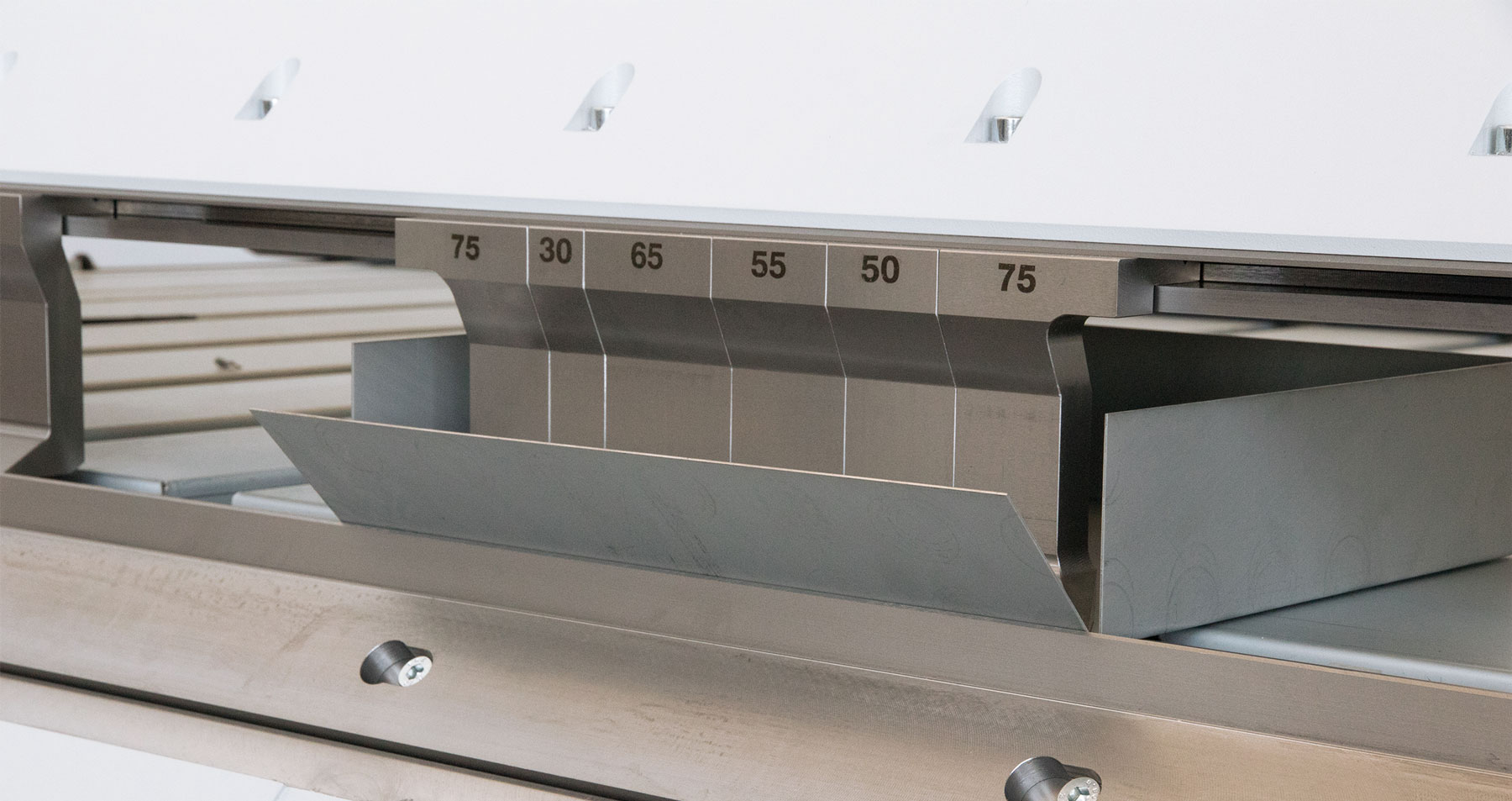

- 30° tapered nose blade, R 1.5

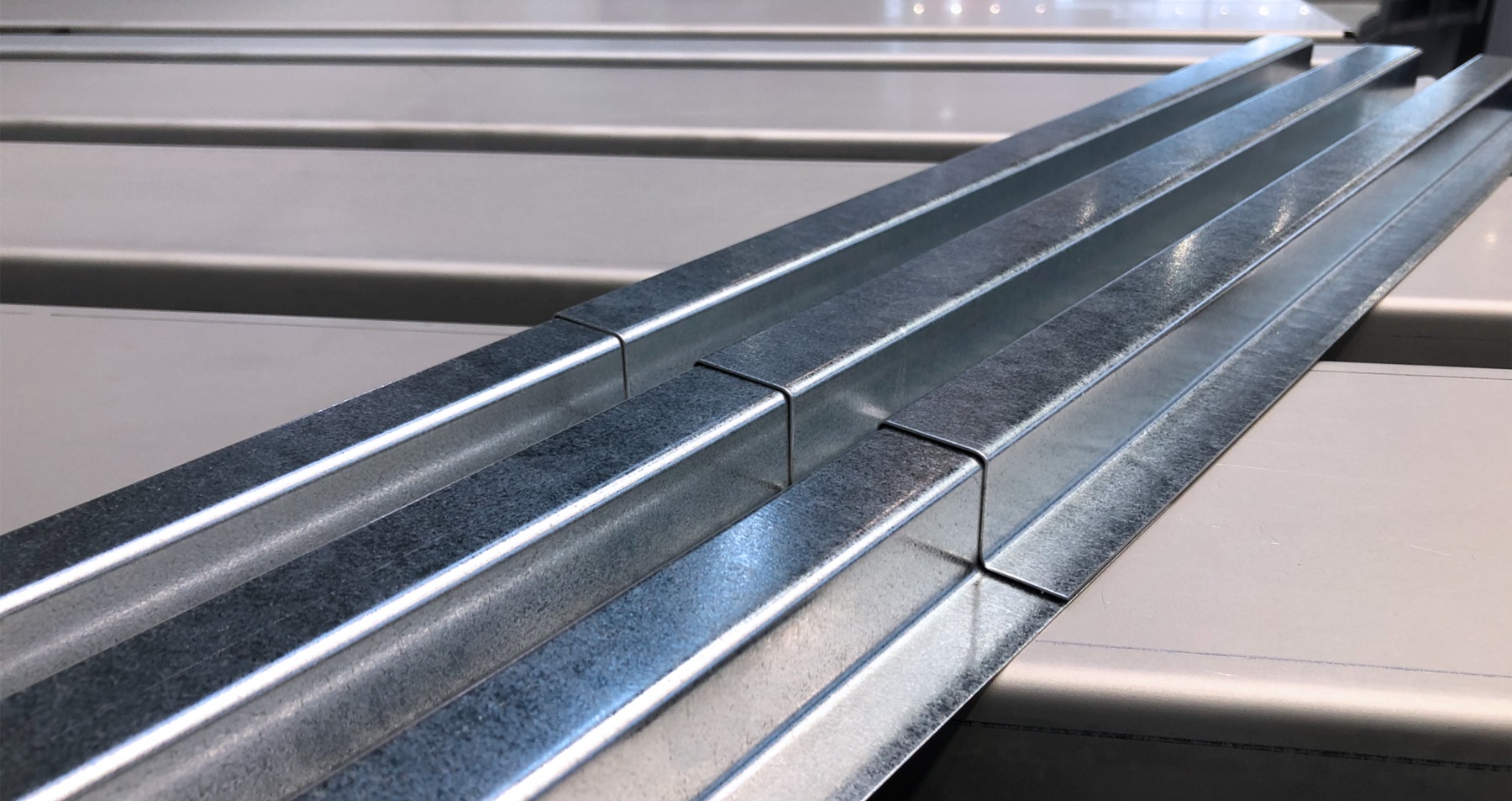

- Folding blade 42 mm, divided

- Bottom blade, in one piece

- Tools with a material strength of 1,100 N/mm².

- Folding beam drive, bilateral

- Clamping beam with recirculated ball screw

- POS 2000 Professional control with positioning template 10 - 1,000 mm incl. sheet metal support table

- Hydraulic tool clamping device for clamping beam

- Clamping beam opening 400 mm

- Central crowning device, manual

- Motorized adjustment of the folding beam, controlled by program

- Coin counter

- Tool set

- Foot control

- Anchor plates