Main features

- Industrial robots from leading manufacturers

- POS 3000 control software

- Automatic tool changer

- Handling systems

- Tables

- Calibration systems

- Highly flexible manipulators for reliable positioning of workpieces

Schroeder bending centers are built on the basis of their modern Evolution series folders, already known for their speed and efficiency under standard operating conditions with manual intervention. However, automation adds an extra dimension to their power. Schroeder's sheet metal working experts can design custom special machines to improve the efficiency of your production processes. Our high-performance swing folders serve as the foundation for our semi- and fully automated bending centers. Using Schroeder technology, hardware and software, we develop tailor-made solutions that range from custom machines to fully automated production lines, operating around the clock. Find out how we can optimize your operations today.

Schroeder bending centers are built on the basis of their modern Evolution series folders, already known for their speed and efficiency under standard operating conditions with manual intervention. However, automation adds an extra dimension to their power. Schroeder's sheet metal working experts can design custom special machines to improve the efficiency of your production processes. Our high-performance swing folders serve as the foundation for our semi- and fully automated bending centers. Using Schroeder technology, hardware and software, we develop tailor-made solutions that range from custom machines to fully automated production lines, operating around the clock. Find out how we can optimize your operations today.

Once programmed, these folders can be operated with minimal effort. The operator simply has to load a sheet and position it against a support, without having to support it in whole or in part. Automatic feeding systems are also available.

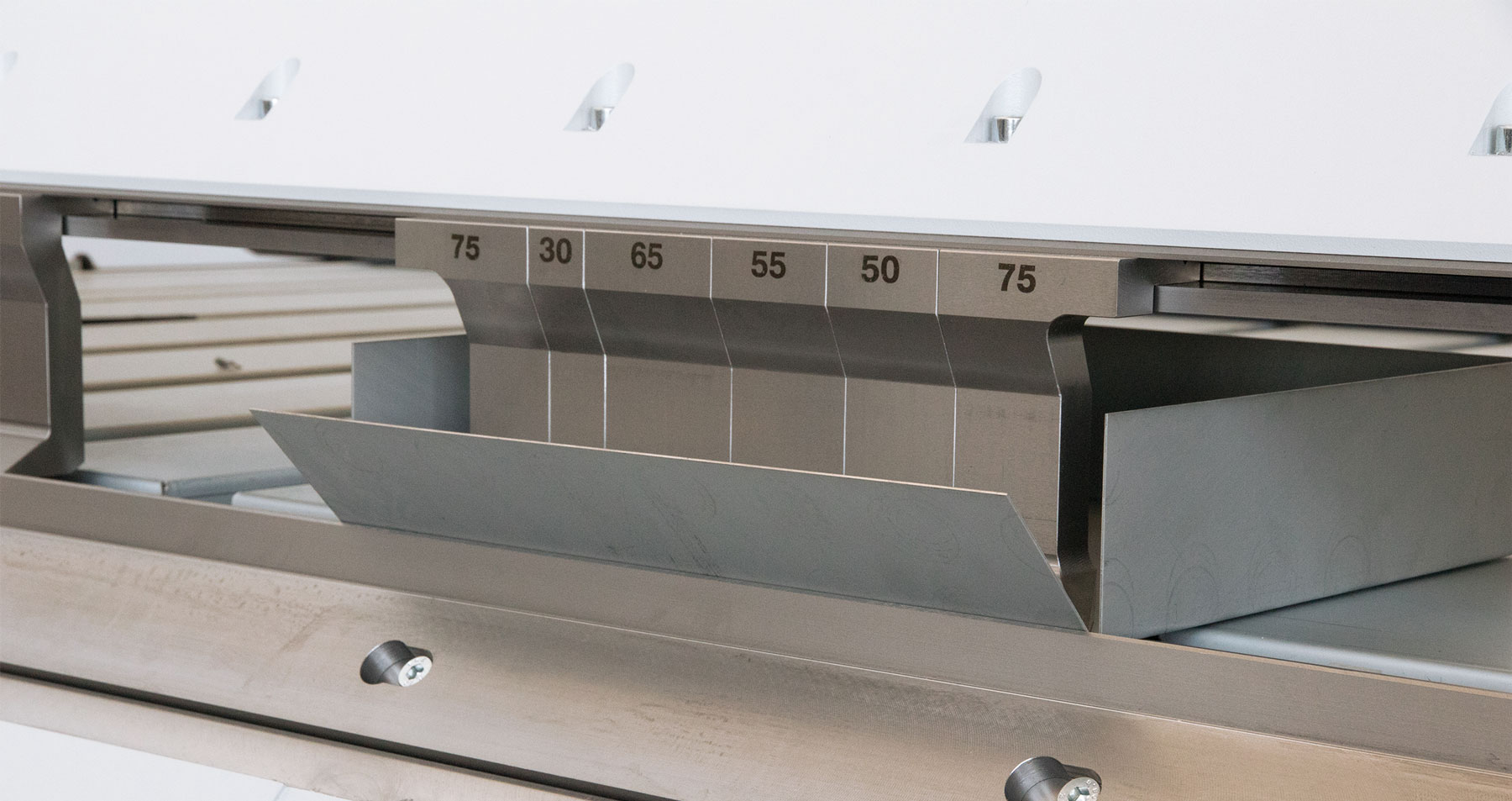

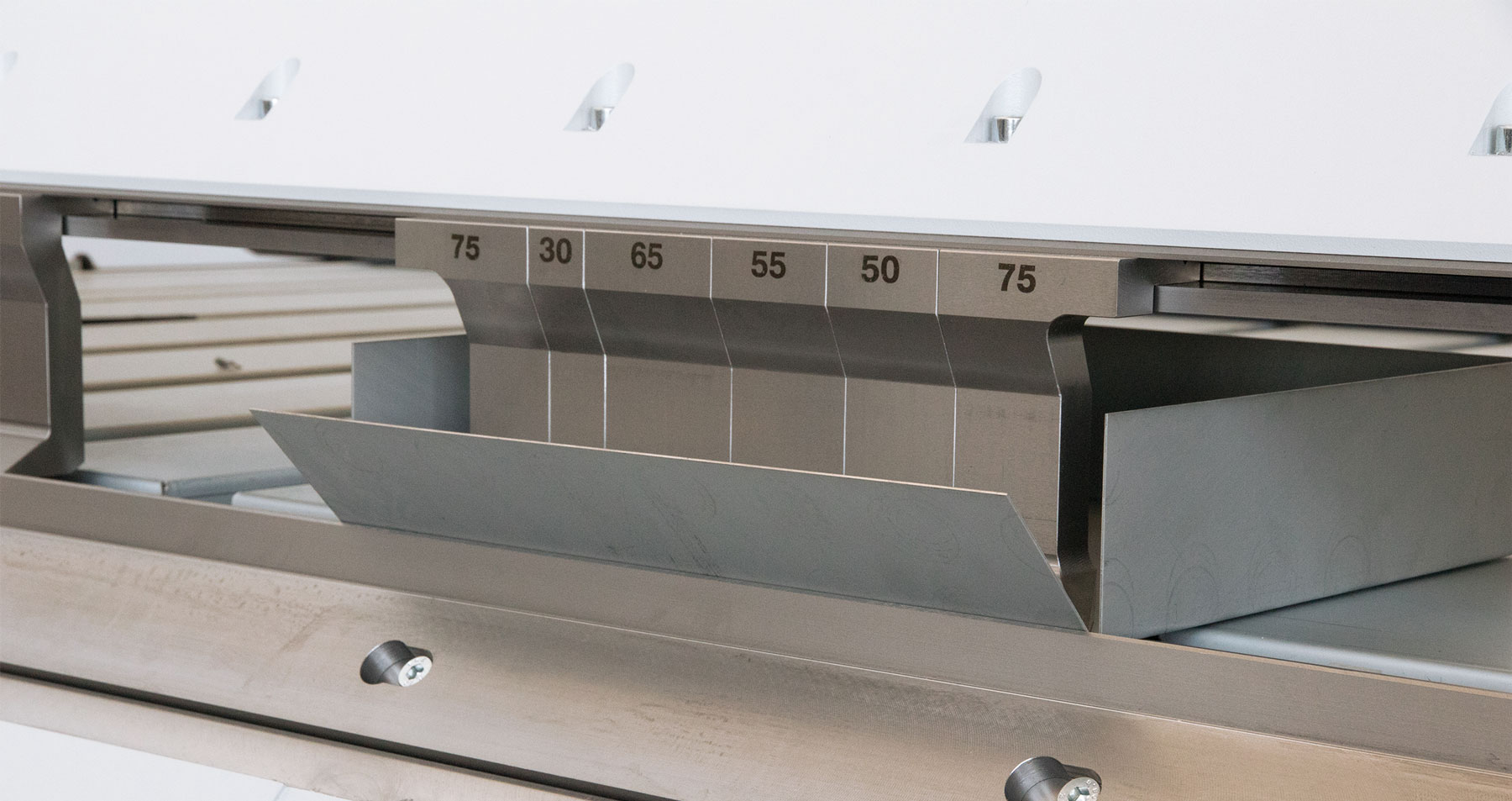

Virtually all bend angles and radii can be obtained with a single tool geometry, even a number of crushed bends.

Start-up times are very quick. You can therefore produce smaller batches of parts just in time, gain efficiency and reduce your inventories.

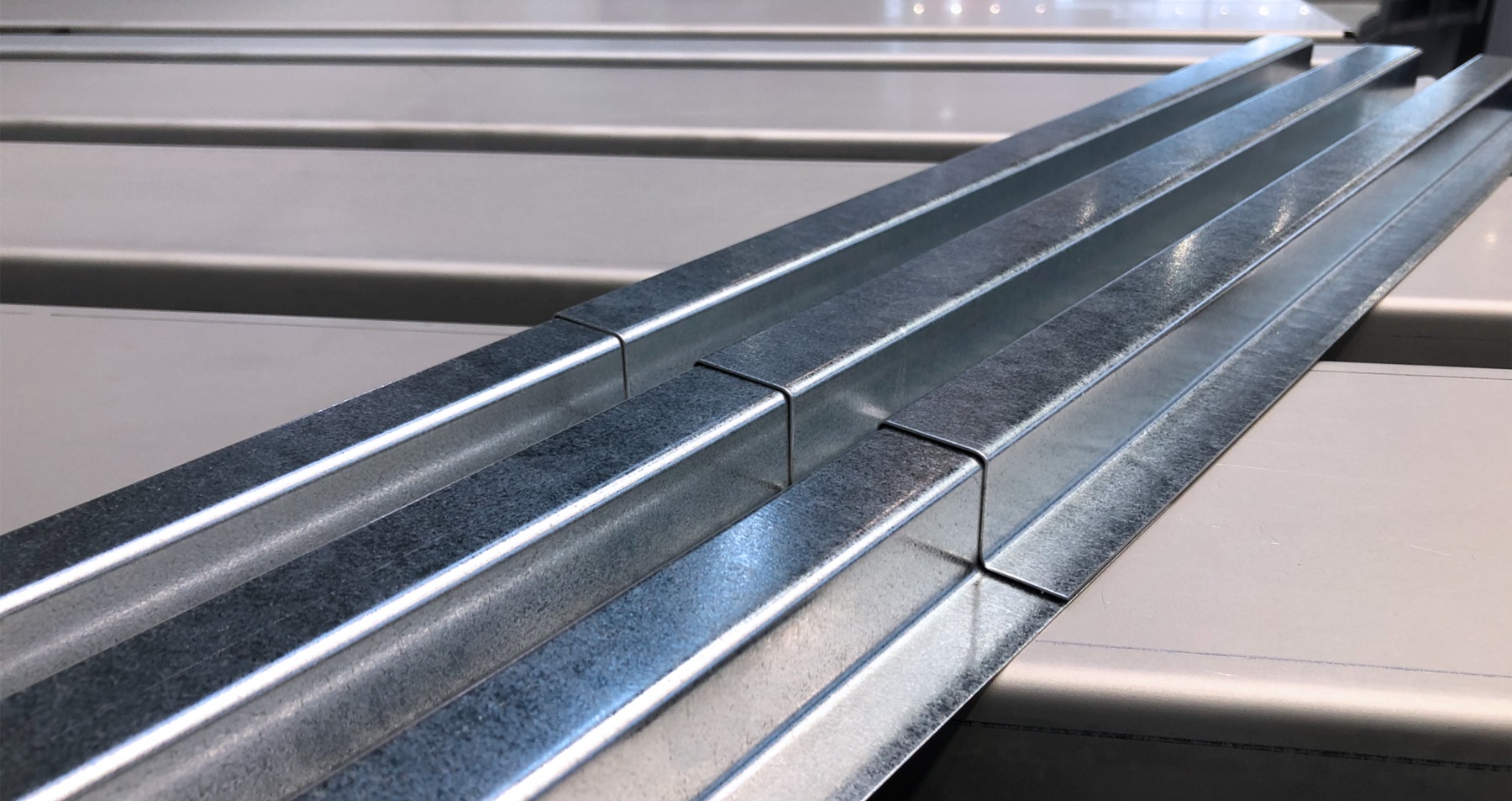

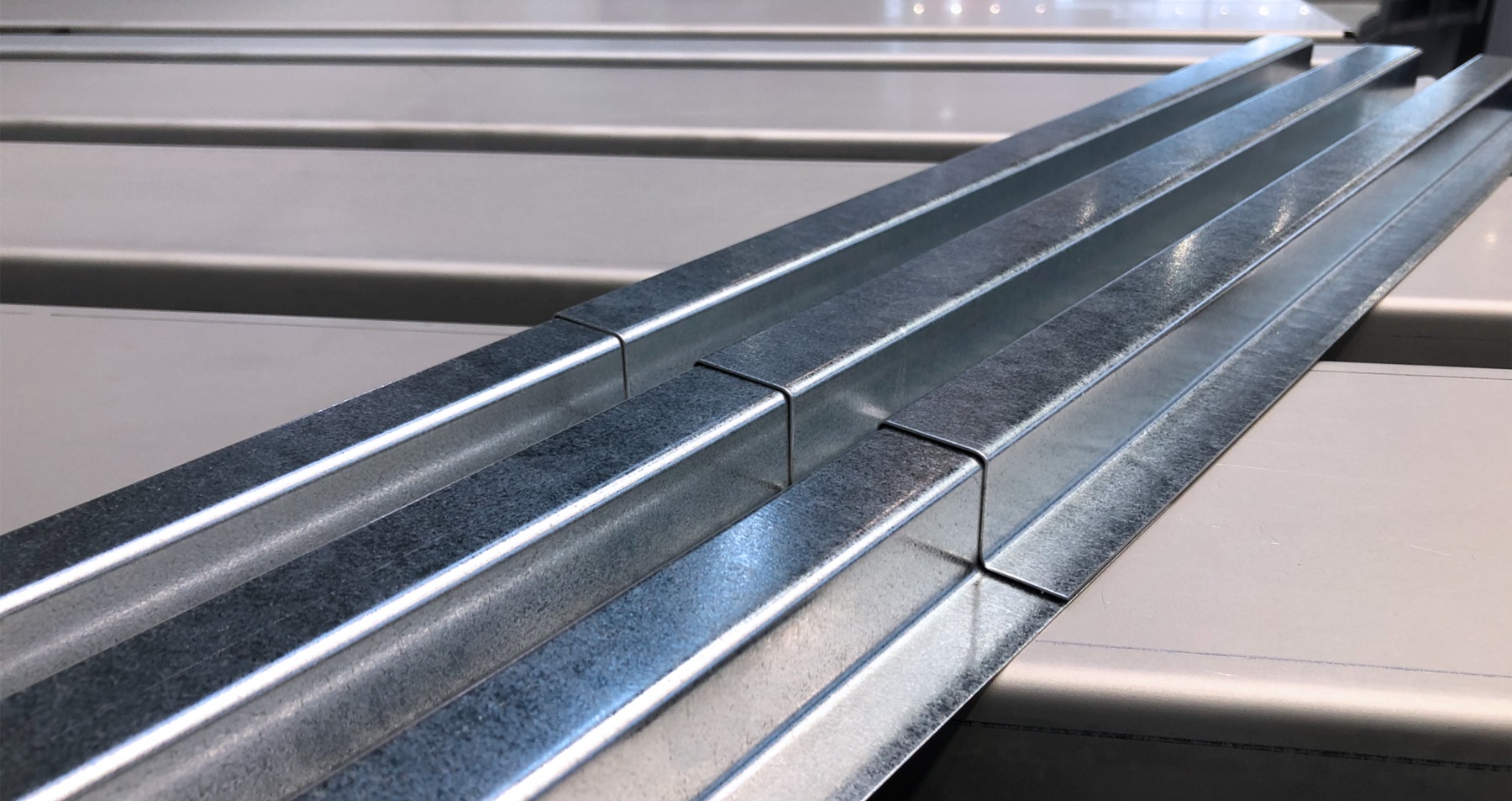

This type of folding offers great precision and excellent repeatability. Additionally, this method produces very little marking on the parts.

In case of malfunction, our team of certified technicians promptly intervenes to ensure the continuity of your production. Equipped with a comprehensive workshop dedicated to machining and welding, we strive to minimize interruptions by conducting precise diagnostics and repairs, whether within our facilities or at your site.

To enhance the operation of your machines or replace a missing part, our subsidiary, Fabtooling, assists you in sourcing and providing specific parts to enhance your production line. Rely on our expertise to find the components necessary for optimizing your equipment.