Main features

- Software Control and Options

- POS 2000 Professional graphic control

- Monitor at the front of the machine integrated into the housing - mobile

- 2nd monitor at the rear movable by guide rail

- PC version (external programming)

- Remote maintenance (connection via RJ45 network cable to be provided by the customer)

- Radius function

- Template

- U-shaped positioning jig: 20 - 1600 mm

- 2 sectors, pneumatically lowerable, ball plate support table, recirculated ball screws (+/- 0.1 mm)

- Clamping beam

- Travel of the clamping beam: 650 mm

- Geometry of the clamping beam: 180°.

- Clamp beam drive: 2x 3.0 kW (converter controlled, trapezoidal spindle)

- Hydraulic tool clamping

- Tilt of the axis of the clamping beam

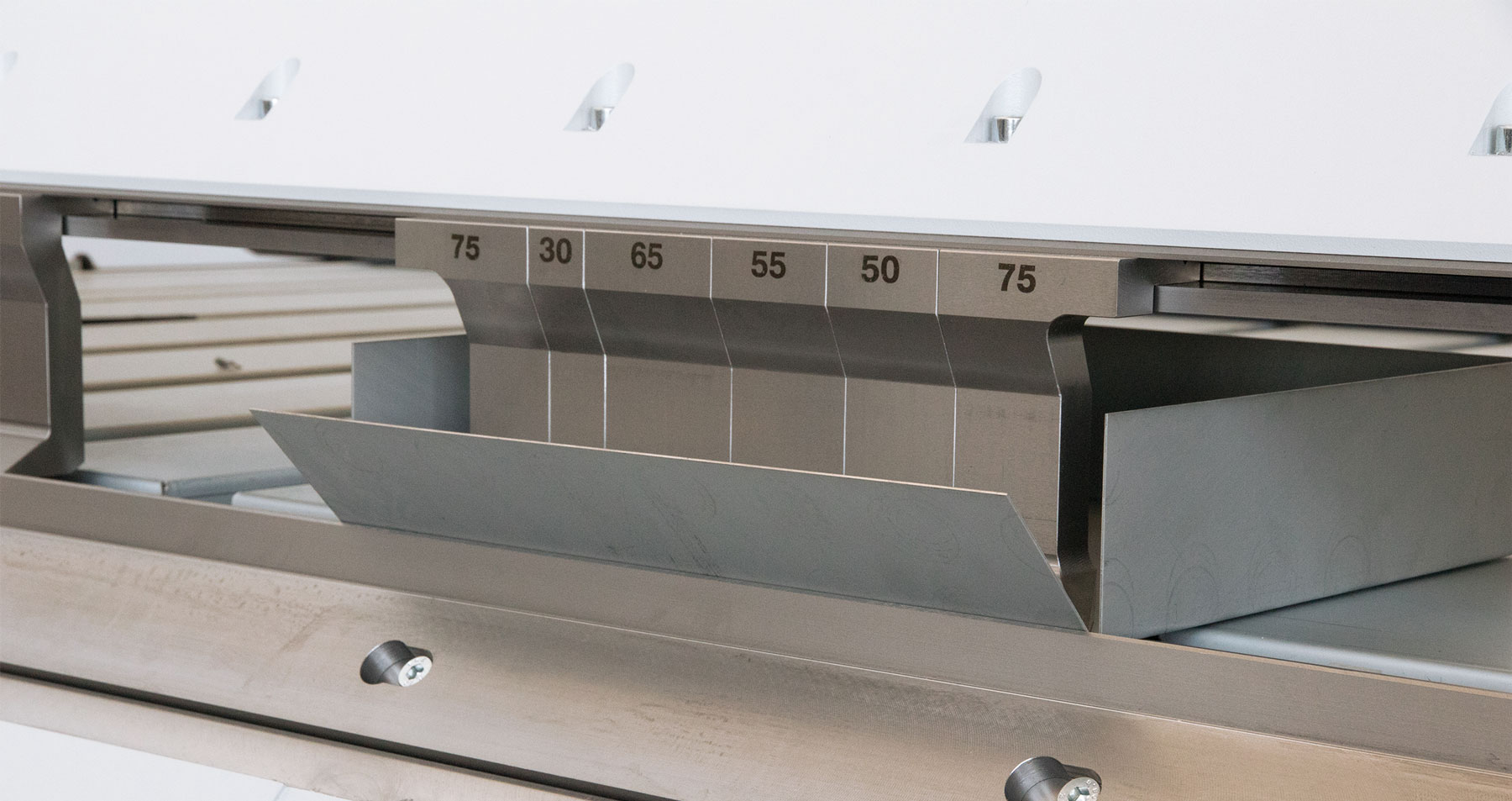

- Display of tool positioning next to the clamping beam

- Folding beam

- Up'n Down folding beam, controlled by program

- Drive 2 x 5.5 kW (with traction motor)

- Hydraulic tool clamping

- Motorized adjustment of the folding beam 160 mm

- Motorized folding center adjustment +80/-15 mm

- Motorized central crowning device

- Lower beam

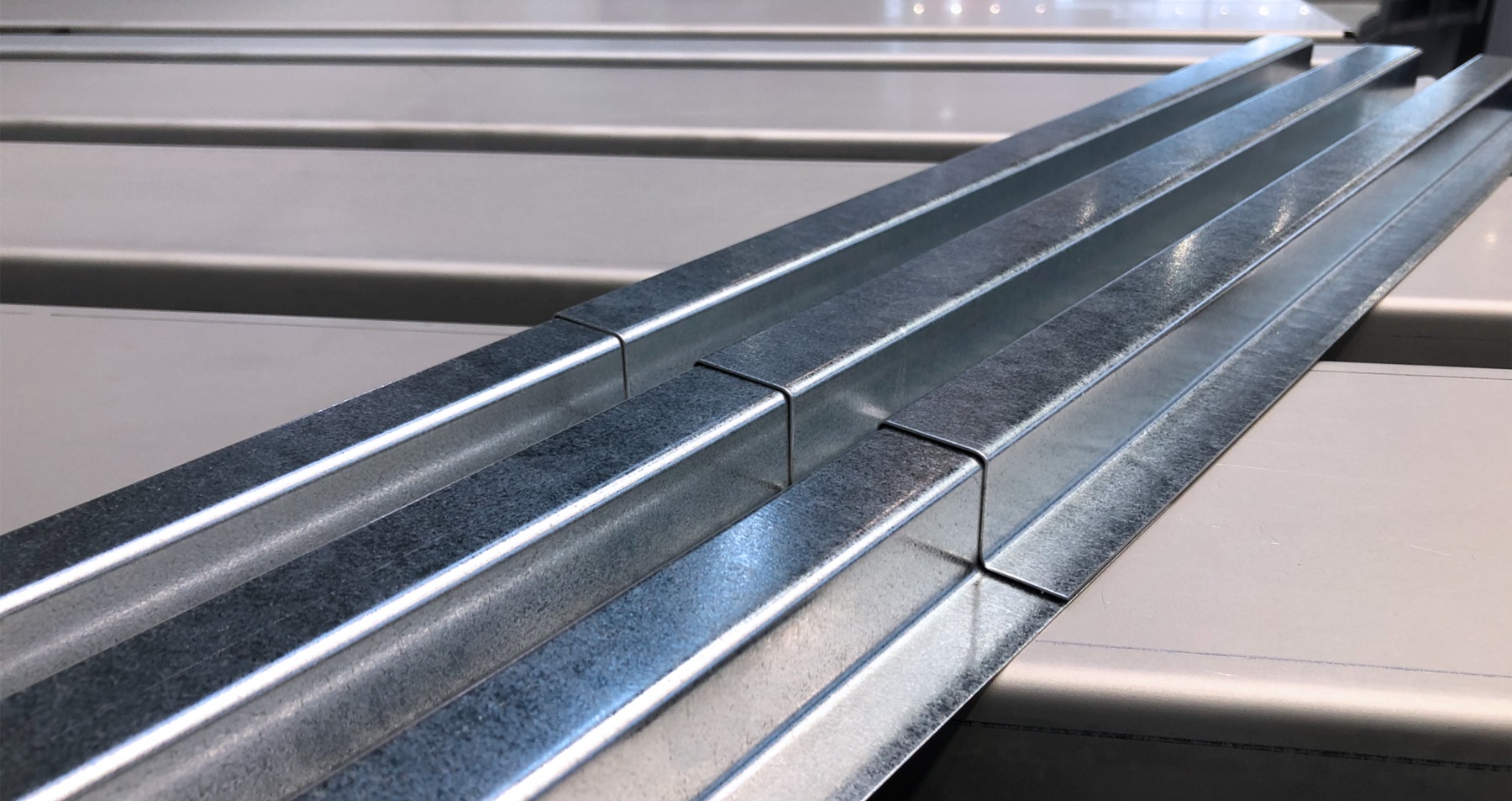

- Lower beam blade approx. 1100 N/mm², one-piece, with finger grooves (minimum thickness) 1100 N/mm², one-piece, with finger grooves (minimum spacing 20 mm)

- Security and others

- Safety access to the front by light barriers

- 2nd pedal on the rail for lateral movement

- Protection against clamping beam/gate by light barrier

- Tools: Standard machine without tools for clamping beam and bending beam

- Air conditioner

- Foot control

- Anchor plates with dowels