EVEN MORE FLEXIBLE APPLICATION POSSIBILITIES

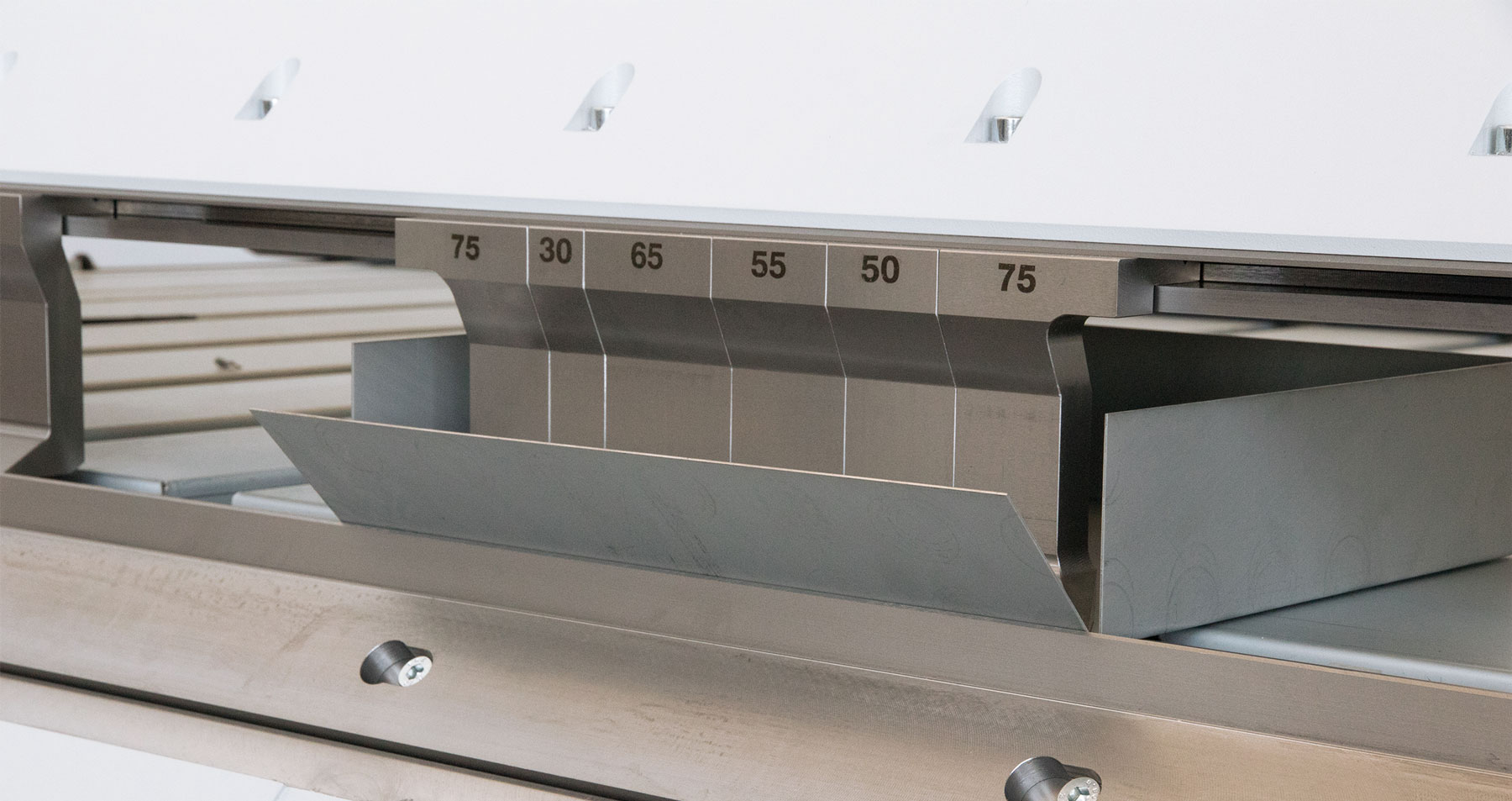

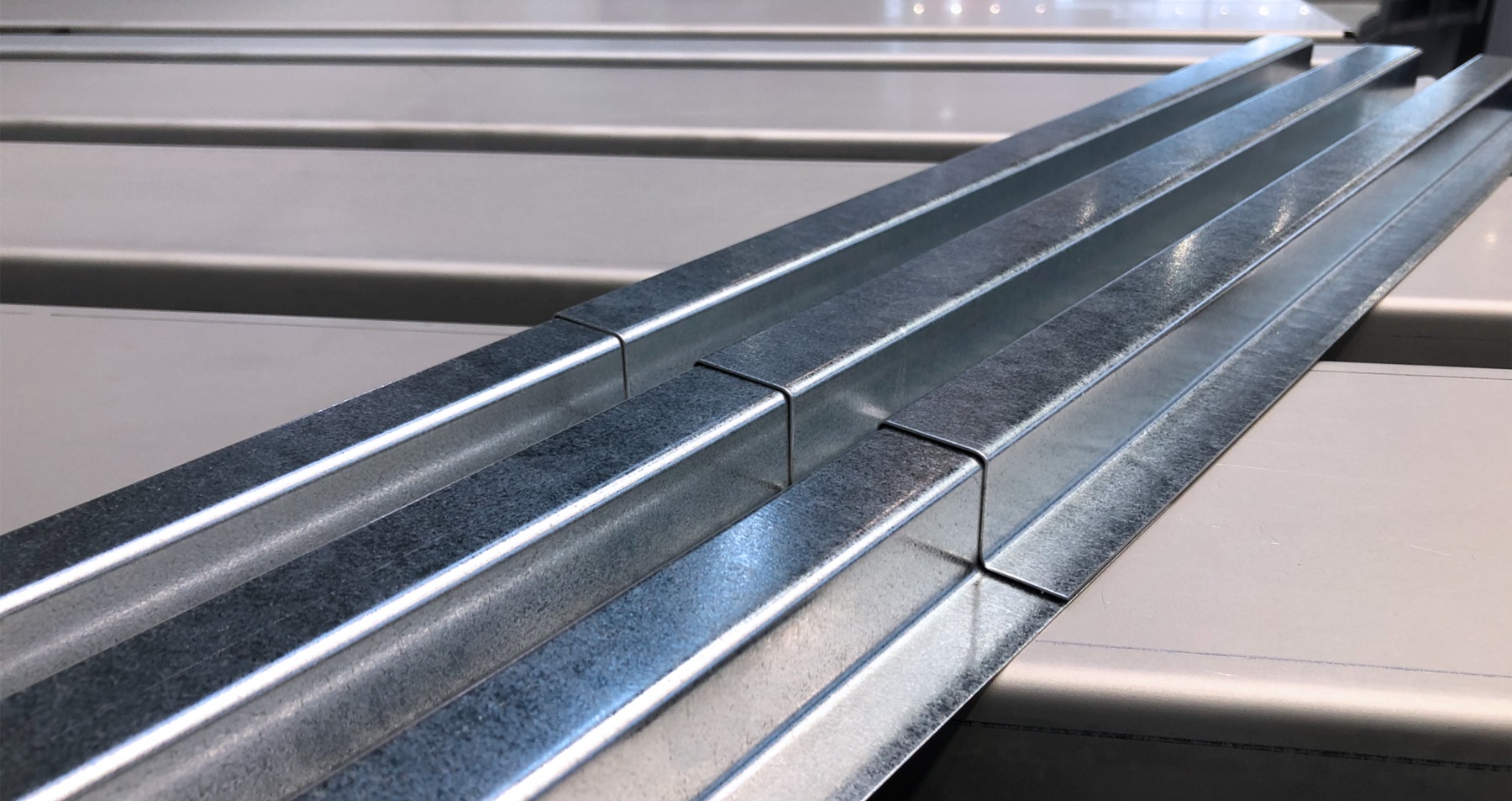

The all-new PowerBend Professional marks the latest generation of the PowerBend series, already recognized for its success in the field of thin sheet metal bending. Equipped with cutting-edge drive technologies, advanced electronic controls, CNC crowning and segmented tooling options, the PowerBend Professional offers the strength, reliability and precision needed to handle complex geometries and difficult bending requirements .

This folder also offers the flexibility your business requires to produce small batches and prototypes. Thanks to the hydraulic tool clamping device and the optional rotating clamping beam, setup times are significantly reduced. The result: increased productivity and reduced labor. The PowerBend Professional is the ideal solution to meet your sheet metal bending needs. Don't miss this opportunity and contact us now to find out more.