THE HIGH-END ROTARY BENDER WITHOUT CHUCK

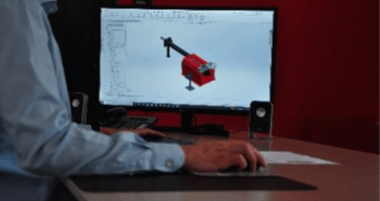

Meet the new ETM 80 Rotary Drawing Bender, a powerful Italian mandrel-less machine designed to bend a variety of tubes and profiles. This strong and precise bender is capable of bending large diameter tubes in both directions, right and left, providing maximum flexibility.

The ETM 80 can bend tubes up to 76 x 6 mm in diameter, achieving bends of over 180 degrees with exceptional finish quality. Made from a single piece of steel, with solid C45 steel dies, it ensures exceptional durability and performance.

Thanks to the "Digital Bend Programming Touch Screen 2" software, specially designed for these machines, using the ETM 80 is both simple and quick. You can select up to 49 programs, each offering 8 bend angles with automatic springback correction, and save your projects for easy repetition. Additionally, the manual rotary positioning table option allows for precise and consistent bends on different planes, making it the ideal machine for a variety of applications, including hydraulic engineering, shipbuilding. and general facilities.