Main features

- Control software

- POS 3000 3-D Graphic control on swivel arm

- Radius function

- Remote maintenance via internet

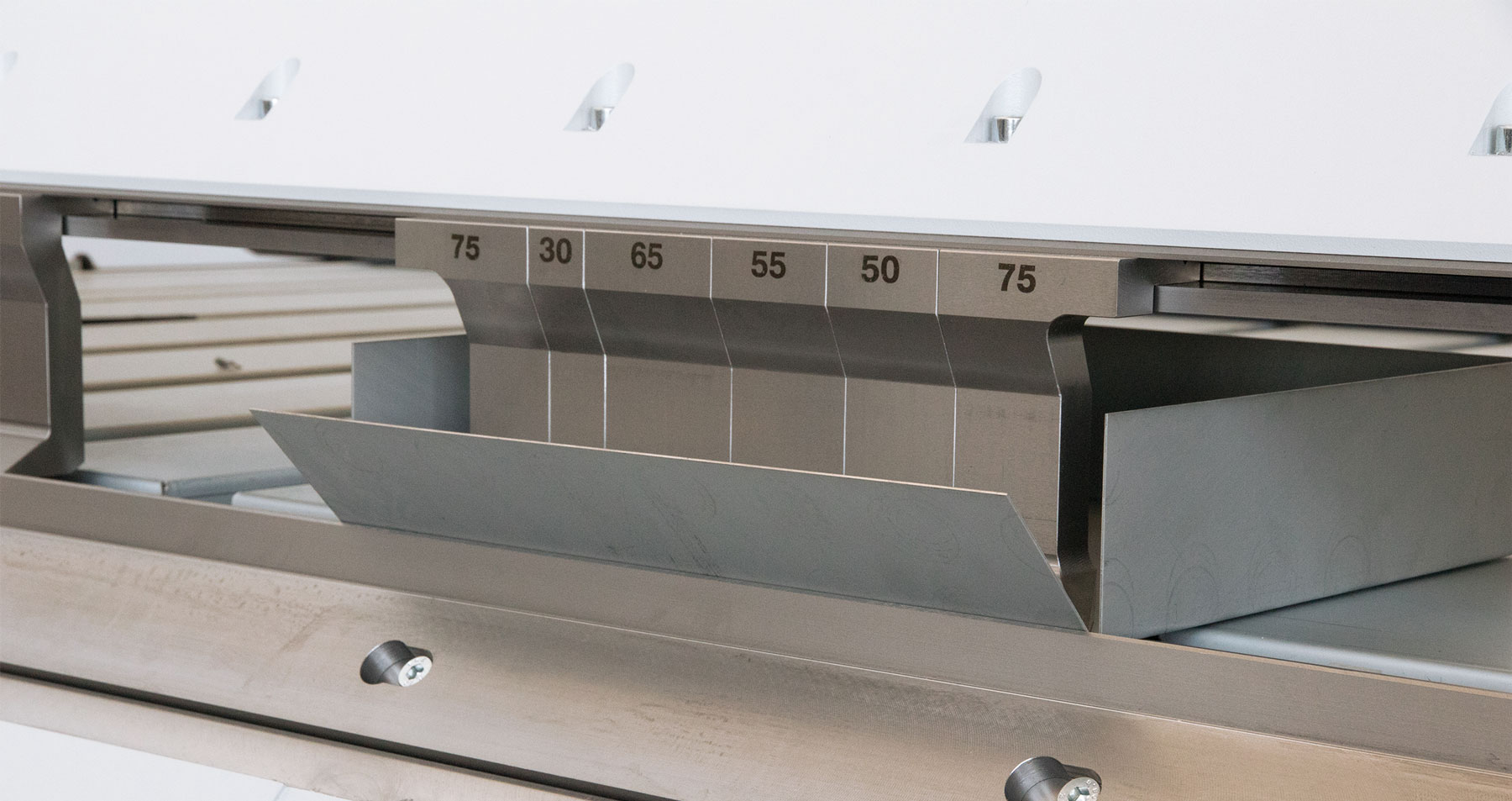

- Rear stop system

- Positioning gauge 10 - 3400 mm, 10 - 4250 mm U-shaped with sectors, retractable pneumatic gauge fingers, steel balls in the sheet support table. 1500 mm square arm left and right. Segmented backing plates can be removed to make room for down clamping applications.

- Clamping beam

- Travel of the clamping beam 650 mm

- Geometry of the clamping beam 180°.

- Hydraulic clamping of the clamping beam

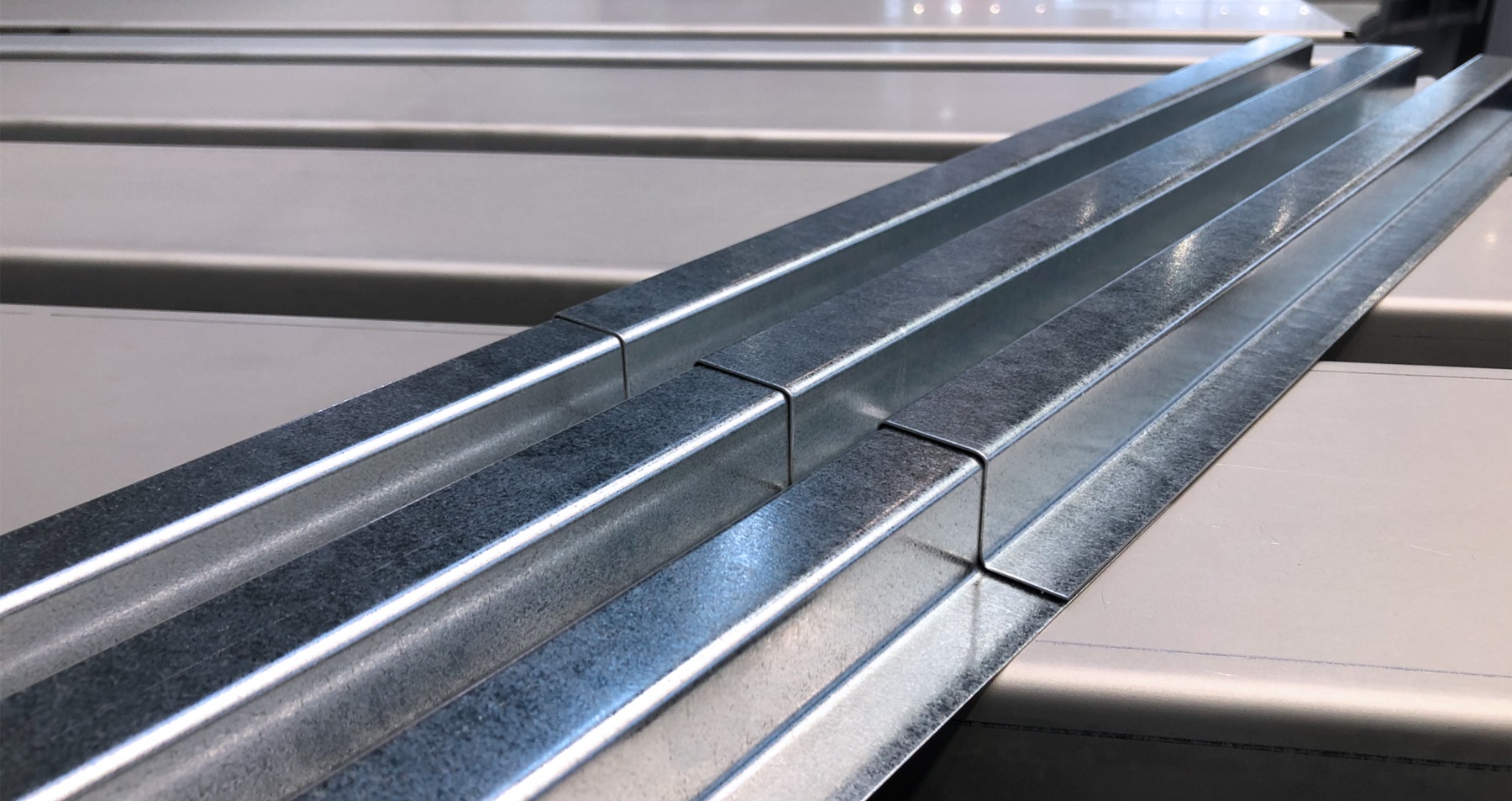

- Folding beam

- Up'n Down folding beam, automatically controlled by POS 3000

- Pneumatic tool clamping device

- Motorized adjustment of the folding beam 200 mm

- Motorized central crowning device

- Center point adjustment, converter control

- Work safety

- Protection by a light barrier controlled by a safety automaton for use from the rear

- Safety kit for use from the front, including second foot control on the rail for lateral movement

- Others

- Foot control

- Anchor plates with dowels

- Tools

- Standard machine without tools