YOUR CUTTING PARTNER FOR LARGE-SCALE PROJECTS

Discover the CARIF 450 BSA VAR-E 18'' semi-automatic band saw, a robust machine designed for medium to large cuts. With a powerful 4 kW drive motor and an electronic panel to adjust the cutting height, this saw offers exceptional precision for your sawing needs.

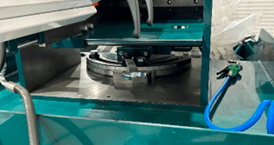

Its solid steel frame and smooth, glossy epoxy finish ensure durability. The CARIF 450 BSA VAR-E is equipped with a patented hydraulic device to adjust the feed and cutting pressure, as well as a 4 kW electric variator operating at 400V. It allows inclined cuts up to -45°/+60° thanks to the rotation of the arch on conical roller bearings, offering great flexibility. This machine is equipped with practical features, such as a pivoting arm console, a potentiometer to memorize the cutting height, and an integrated coolant tank. It also comes with a 3660x34x1.1mm Bimetal M42 blade, service keys, instruction manual and spare parts for a complete and efficient cutting experience. Improve your cutting operations with the CARIF 450 BSA VAR-E.