FOR BIG JOBS

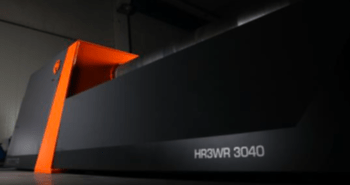

The Roccia 3-Roller Series Plate Roller, model HR3WS, embodies the union of proven German engineering and renowned Italian design. Designed to satisfy the most demanding needs, this model stands out for its unique design.

With its two side rollers moving horizontally and its upper roller moving up and down, this roller with variable geometry adapts to a wide variety of tasks. While it may not be the fastest, its versatility makes it a compelling choice. The adjustment range of the side rollers combines performance and flexibility, even allowing you to use it as a press to obtain very short flat edges.

Available in several versions, ranging from 1 to 8 meters in plate length and with a thickness of 1 mm to 300 mm, you will certainly find the model that will meet your production needs.